Plastic Caps and Closures Manufacturing Plant Project Report 2025 Edition

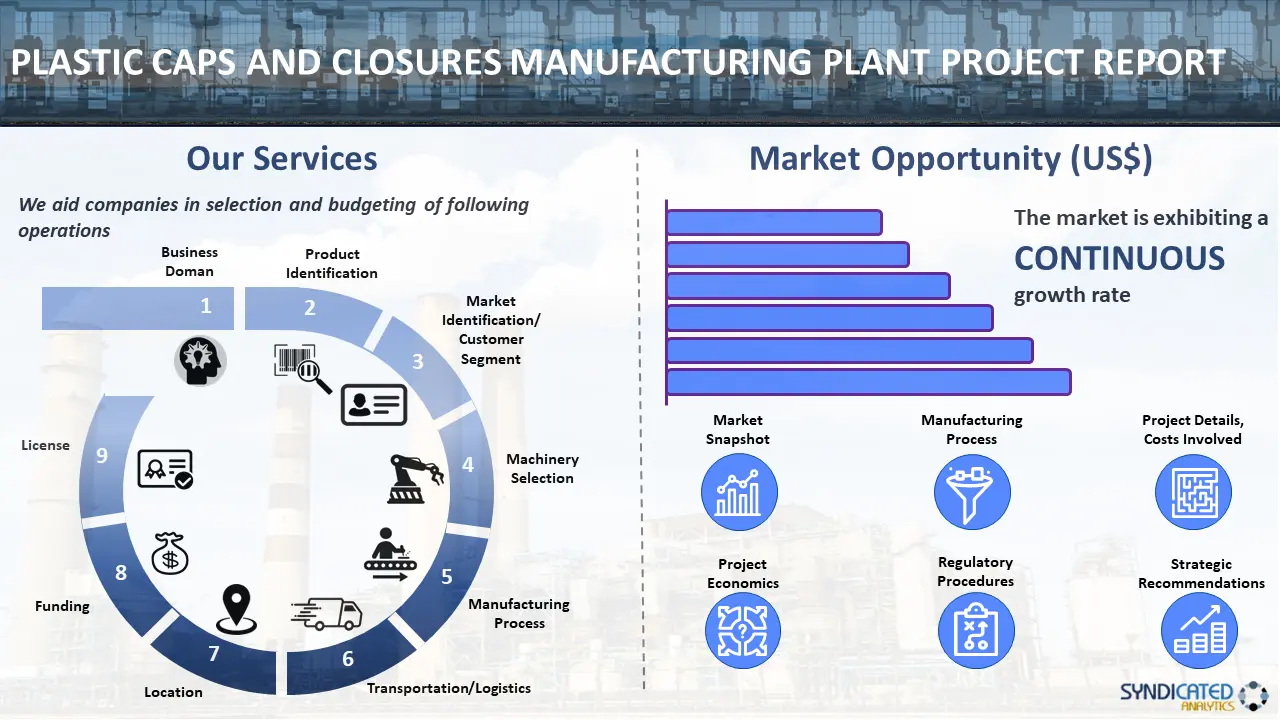

Report Coverage: Industry Analysis (Market Performance, Segments, Price Analysis, Outlook), Detailed Process Flow (Product Overview, Unit Operations, Raw Materials, Quality Assurance), Requirements and Cost (Machinery, Raw Materials, Packaging, Transportation, Utility, Human Resource), Project Economics (Capital Investments, Operating Costs, Profit Projections, Financial Analysis, Revenue), and Investment Opportunities

Report Overview:

Syndicated Analytics report, titled “Plastic Caps and Closures Manufacturing Plant Project Report 2025 Edition: Industry Analysis (Market Performance, Segments, Price Analysis, Outlook), Detailed Process Flow (Product Overview, Unit Operations, Raw Materials, Quality Assurance), Requirements and Cost ( Machinery, Raw Materials, Packaging, Transportation, Utility, Human Resource), Project Economics (Capital Investments, Operating Costs, Profit Projections, Financial Analysis, Revenue), and Investment Opportunities ,” provides a complete roadmap for setting up a plastic caps and closures manufacturing plant. It covers a comprehensive market overview to micro-level information such as unit operations involved, raw material requirements, utility requirements, infrastructure requirements, machinery and technology requirements, manpower requirements, packaging requirements, transportation requirements, etc. The report provides detailed insights into project economics, including capital investments, project funding, operating expenses, income and expenditure projections, fixed costs vs. variable costs, direct and indirect costs, expected ROI and net present value (NPV), profit and loss account, financial analysis, etc. This report is a must-read for entrepreneurs, investors, researchers, consultants, and business strategists with a stake in the plastic caps and closures industry. It provides an in-depth analysis of the industry's current state and future potential, offering valuable insights for decision-making and strategy development. The report is an indispensable resource that offers a detailed examination of the plastic caps and closures industry. It is a valuable tool for anyone seeking to establish a foothold in this dynamic sector.

Plastic caps and closures are essential components in packaging, providing a secure and convenient means of sealing various containers. They are typically made from thermoplastic materials such as polyethylene, polypropylene, or polystyrene and are designed to fit tightly onto bottles, jars, and other containers, preventing leakage and contamination and ensuring product freshness. Plastic caps and closures come in diverse shapes and sizes to accommodate different packaging needs, ranging from flip-top caps for personal care products to tamper-evident closures for pharmaceuticals and child-resistant caps for household chemicals. Their versatility extends to the food and beverage industry, where screw caps, snap-on lids, and dispensing closures are widely used. The lightweight and cost-effective nature of plastic makes these closures popular in packaging, contributing to their prevalence across various industries and applications.

Market Trends/Drivers:

The global plastic caps and closures market is witnessing significant growth, driven by the escalating demand for convenience and user-friendly packaging solutions across diverse industries. In confluence with this, the versatile design of plastic caps and closures, offering easy resealing and dispensing functionalities that meet consumer preferences for hassle-free usage, is contributing to the market growth. Moreover, the continuous growth of the food and beverage (F&B) industry, wherein plastic caps and closures are widely employed in packaging for beverages, sauces, condiments, and other consumables, catering to the increasing demand for packaged and convenience foods is creating a positive outlook for market expansion. Concurrently, the pharmaceutical and healthcare sector's emphasis on safety and tamper-evident packaging solutions spurring the demand for specialized closures that ensure the integrity of medicinal products are providing an impetus to the market growth. In addition to this, the ongoing trend of sustainable packaging practices, with manufacturers increasingly focusing on developing eco-friendly closures, utilizing recycled materials, or exploring biodegradable options, is acting as another significant growth-inducing factor. Furthermore, the burgeoning growth of the personal care and cosmetics industry, where plastic closures, such as flip-tops, disc tops, and pump dispensers are employed in skincare, haircare, and cosmetic products for functionality and aesthetics purposes, is strengthening the market growth. Apart from this, the flourishing expansion of the beverage industry, particularly in the bottled water and non-alcoholic beverage segments, is presenting lucrative opportunities for market expansion.

The project report provides a comprehensive analysis of the plastic caps and closures market, covering various critical aspects. The following sections are included:

Market Overview:

- Market Performance Analysis

- Regional Coverage

- Key Market Segmentation

- Price Trend Analysis

- COVID-19 Impact Analysis

- Market Forecast and Outlook

- Key Market Players

The report provides an analysis of the global plastic caps and closures market performance, market breakup by segment and region, price trends, key market players and impact of COVID-19 on the market. Additionally, it offers insights into the market outlook, including growth opportunities and challenges that may impact the industry's future.

Manufacturing Operations:

- Product Description and Insights

- Detailed Process Flow Analysis

- Identification of Unit Operations Involved

- Mass Balance Analysis and Raw Material Requirements

- Quality Control

The report offers a detailed insight into the manufacturing process for plastic caps and closures. It covers the product insights, the process flow, unit operations involved, quality control, as well as the mass balance and raw material requirements involved.

Project Requirements, Details, and Costs:

- Site Development, Location, and Land Requirements

- Plant Layout

- Machinery Requirements and Associated Costs

- Raw Material Requirements and Associated Costs

- Packaging Requirements and Associated Costs

- Transportation Requirements and Associated Costs

- Utility Requirements and Associated Costs

- Manpower Requirements and Associated Costs

This section covers the project details, requirements, and costs involved in setting up a plastic caps and closures manufacturing plant. It provides information on land, location, and site development, plant layout, machinery requirements and expenditures, raw material and packaging requirements and expenditures, transportation requirements and expenditures, utility requirements and expenditures, as well as manpower requirements and expenditures.

Project Financial Analysis:

- Capital Investments Analysis

- Operating Costs Analysis

- Expenditure Projections Analysis

- Revenue Projections Analysis

- Taxation and Depreciation Analysis

- Profit Projections Analysis

- Comprehensive Financial Analysis

The report also covers a comprehensive analysis of the project economics for setting up a plastic caps and closures manufacturing plant. This includes the analysis of capital expenditure (CapEx), operating expenditure (OpEx), income projections, taxation, depreciation, liquidity analysis, profitability analysis, payback period, NPV, uncertainty analysis, and sensitivity analysis.

Customized Solutions and Report Features:

The report can be customized based on your specific requirements. This may include information on the country/region you plan to set up your plant, manufacturing capacity, machinery suppliers and costs, and any additional scope requirements. Some of the customizations requested by our clients include:

- Customization based on the location of your plant

- Manufacturing capacity customization

- Machinery supplier and cost customization

- Additional scope based on your specific needs

The report offers valuable insights into the plastic caps and closures market, covering critical aspects such as market performance, manufacturing processes, project details, project economics, and key success and risk factors. With its comprehensive analysis, it is an essential resource for entrepreneurs, investors, researchers, consultants, and business strategists interested in the industry.

Report Scope:

| Report Features | Details |

|---|---|

| Product Name | Plastic Caps and Closures |

| Report Coverage | Detailed Process Flow: Unit Operations Involved, Quality Assurance Criteria, Technical Tests, Mass Balance, and Raw Material Requirements Land, Location and Site Development: Selection Criteria and Significance, Location Analysis, Project Planning and Phasing of Development, Environmental Impact, Land Requirement and Costs Plant Layout: Importance and Essentials, Layout, Factors Influencing Layout Plant Machinery: Machinery Requirements, Machinery Costs, Machinery Suppliers (Provided on Request) Raw Materials: Raw Material Requirements, Raw Material Details and Procurement, Raw Material Costs, Raw Material Suppliers (Provided on Request) Packaging: Packaging Requirements, Packaging Material Details and Procurement, Packaging Costs, Packaging Material Suppliers (Provided on Request) Other Requirements and Costs: Transportation Requirements and Costs, Utility Requirements and Costs, Energy Requirements and Costs, Water Requirements and Costs, Human Resource Requirements and Costs Project Economics: Capital Costs, Techno-Economic Parameters, Income Projections, Expenditure Projections, Product Pricing and Margins, Taxation, Depreciation Financial Analysis: Liquidity Analysis, Profitability Analysis, Payback Period, Net Present Value, Internal Rate of Return, Profit and Loss Account, Uncertainty Analysis, Sensitivity Analysis, Economic Analysis Other Analysis Covered in The Report: Market Trends and Analysis, Market Segmentation, Market Breakup by Region, Price Trends, Competitive Landscape, Regulatory Landscape, Strategic Recommendations, Case Study of a Successful Venture |

| Currency | US$ (Information can also be provided in the local currency) |

| Pricing and Purchase Options | Single User License: US$ 3450 Five User License: US$ 4450 Corporate User License: US$ 5450 |

| Customization Scope | The report can also be customized based on the requirement of the customer |

| Post-Sale Analyst Support | 12-14 Weeks |

| Delivery Format | PDF and Excel through email (We can also provide the editable version of the report in PPT/Word format on special request) |

The report also answers several key questions for stakeholders who are planning to enter the plastic caps and closures market. Some of these include:

- What are the major success and risk factors in the global plastic caps and closures industry?

- How has the global plastic caps and closures market performed thus far and what is its future outlook?

- What is the industry's structure and who are the key players?

- What unit operations are involved in a plastic caps and closures manufacturing plant?

- How much land is required for a plastic caps and closures manufacturing plant?

- What machinery is required for a plastic caps and closures manufacturing plant?

- What are the raw materials needed for a plastic caps and closures manufacturing plant?

- What utility requirements are there for a plastic caps and closures manufacturing plant?

- What is the manpower requirement for a plastic caps and closures manufacturing plant?

- What is the infrastructure cost for a plastic caps and closures manufacturing plant?

- What are the capital costs for a plastic caps and closures manufacturing plant?

- What are the operating costs for a plastic caps and closures manufacturing plant?

- What is the pricing mechanism for plastic caps and closures?

- What are the income and expenditure for a plastic caps and closures manufacturing plant?

- How long does it take to break-even?

Why Our Reports Stand Out:

- Gain valuable insights into your business venture's potential, allowing you to make informed decisions.

- Access a global network of consultants and domain experts in 100+ countries across North America, Europe, Asia Pacific, South America, Africa, and the Middle East.

- Benefit from our extensive database of equipment and raw material suppliers from all major continents.

- Stay up-to-date with the latest global data on land costs, construction costs, utility costs, labor costs, and more in 100+ countries.

- Join a diverse range of satisfied clients, including Fortune 500 companies, governments, institutions, and small startups.

- Receive support from our expert in-house team of engineers, statisticians, modeling experts, chartered accountants, architects, and more, who have played a critical role in building, expanding, and optimizing sustainable manufacturing plants worldwide.

Purchase Options

Ask For Customization

Personalize this research

Triangulate with your own data

Get data as per your format and definition

Gain a deeper dive on a specific application, geography, customer or competitor

Any level of personalization

Get in Touch

Call us on

US: +1-213-316-7435

Uk: +44-20-8040-3201

Drop us an email at

sales@syndicatedanalytics.com